Tesla's Secret Battery Revolution Dry Electrode Batteries YouTube

To address the multitude of issues that accompany wet electrode fabrication techniques, composite lithium-ion battery (LIB) electrodes composed of solely active components (active battery material and conductive additive) are fabricated using a scalable and eco-friendly dry processing method known as dry pressing. To accomplish this, a nanoporous carbon allotrope (i.e., holey graphene or hG.

Lithium Ion Battery Electrode Company News News Xiamen TOB New

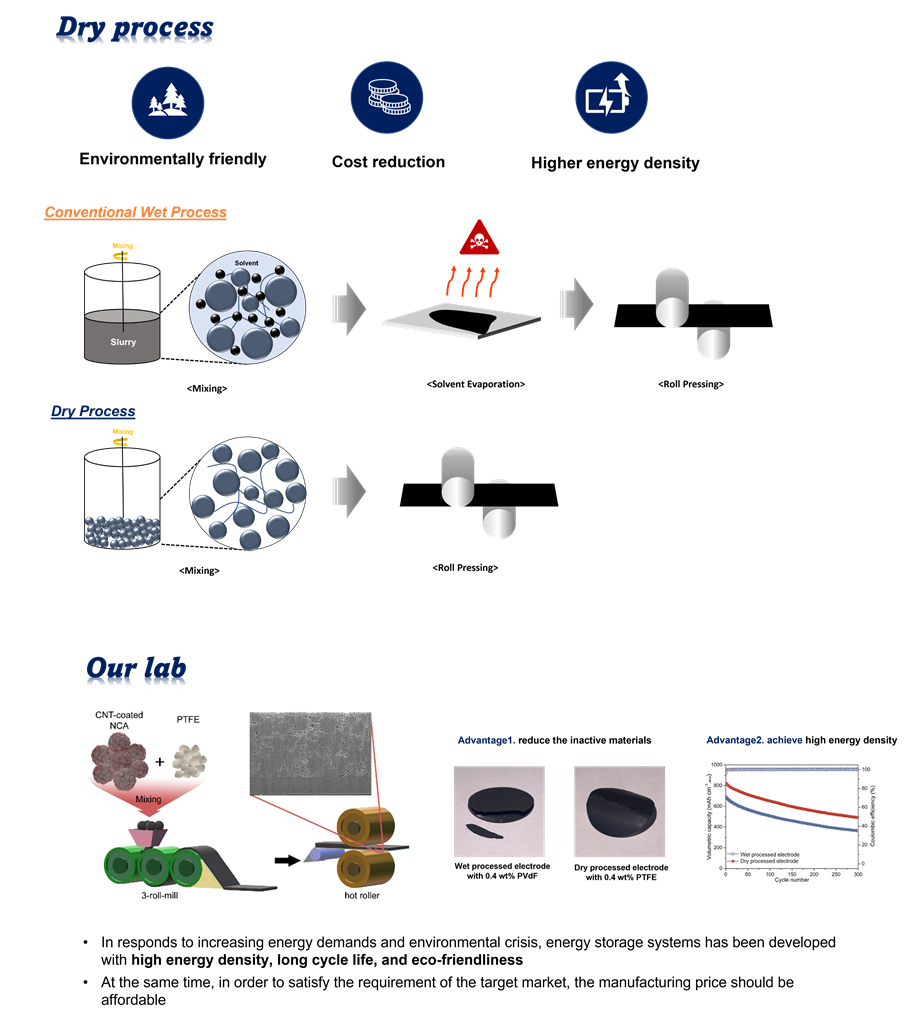

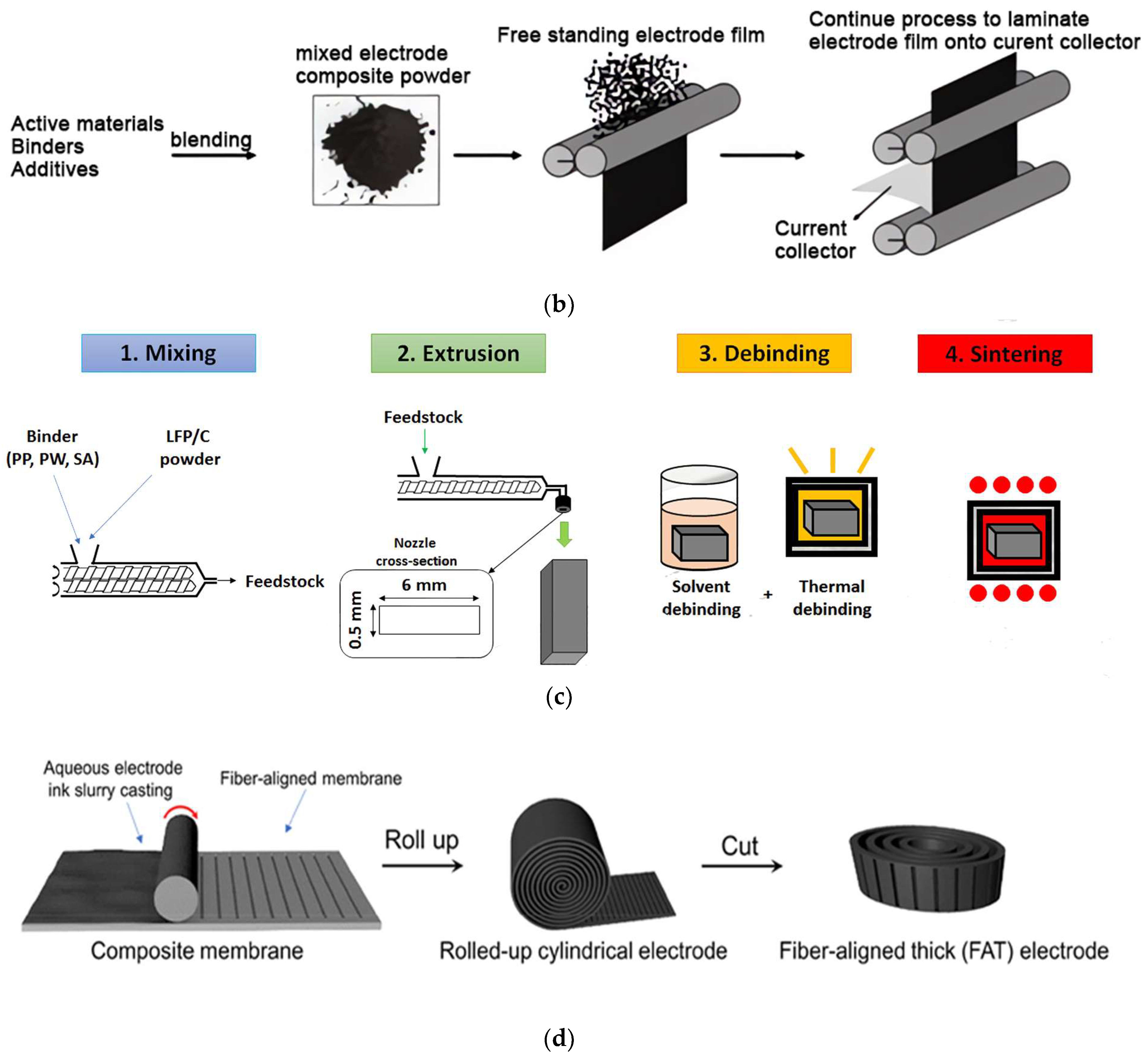

Dry battery electrode (DBE) is an emerging concept and technology in the battery industry that innovates electrode fabrication as a "powder to film" route. The process shortens the time and energy it takes, and minimizes space needed, compared with wet process fabrication (coating the electrode foil with a wet, chemical slurry).

전기화학 나노 에너지 소재 및 디바이스 연구실 Research LIBs Dry electrode process

Dry battery electrode (DBE) is an emerging concept and technology in the battery industry that innovates electrode fabrication as a "powder to film" route. The DBE technique can.

Solventfree manufacturing process (a) schematic of dry electrostatic

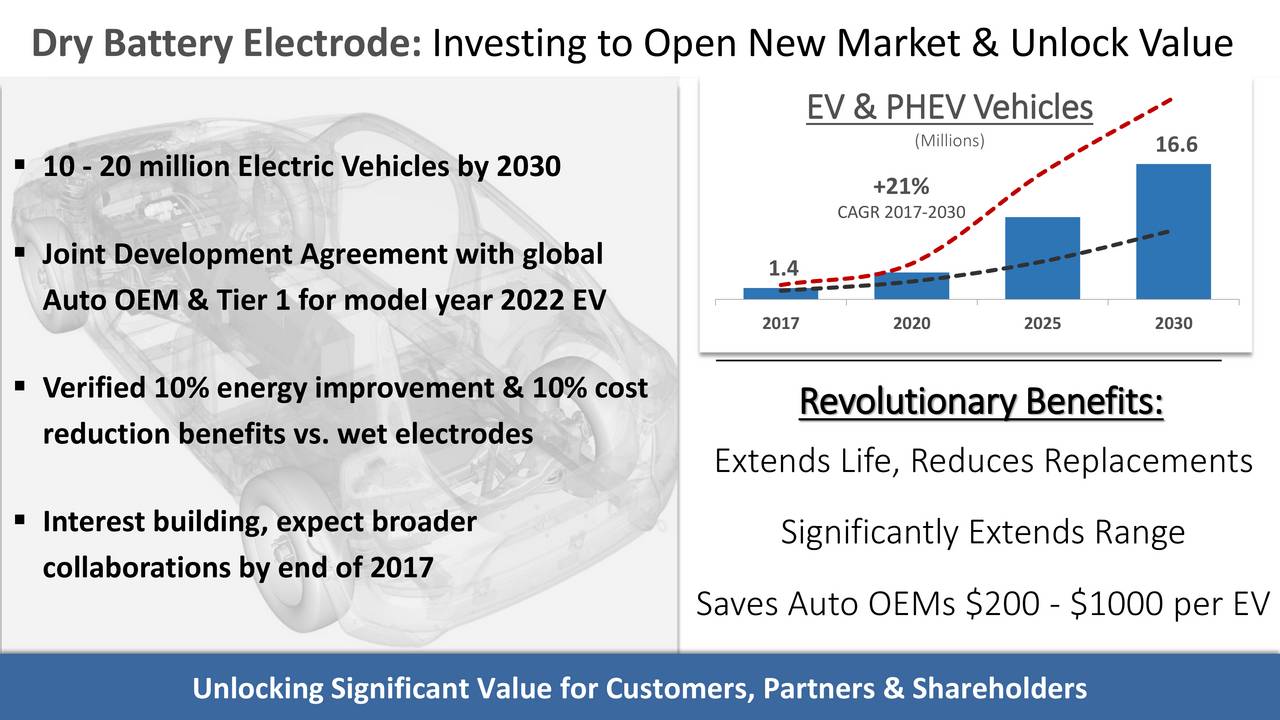

2018. 2. PDF. 1 Excerpt. In this paper we report a truly solventless dry battery electrode (DBE) coating technology developed by Maxwell Technologies that can be scalable for classical and advanced battery chemistry. Unlike conventional slurry cast wet coated electrode, Maxwell's DBE offers significantly high loading and produces a thick.

All solid state battery dry electrode process, advantages and

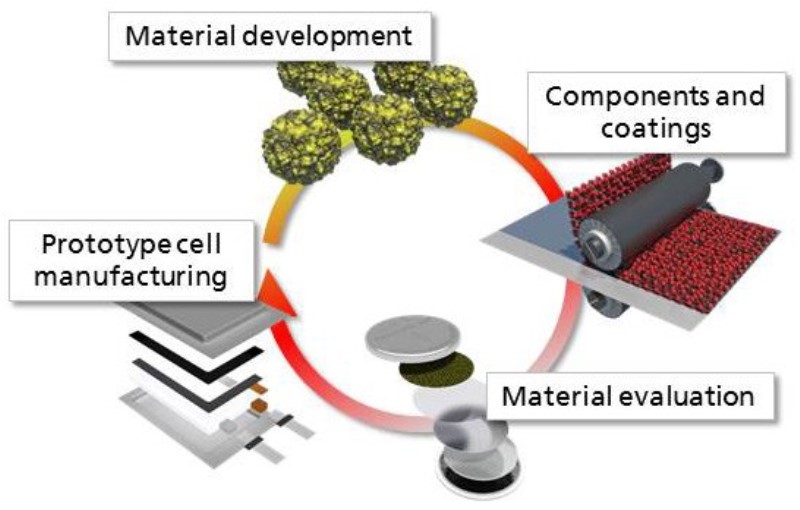

Dry mixing is a key technology in the manufacture of solid-state batteries, which determines the quality and production efficiency of battery electrodes. Dry coating There are several main categories, the first Maxwell dry electrode.

Dry Transfer Coating for Tomorrow's EVs News about Energy Storage

1. Introduction The pursuit for the sustainable development of society and the goal of carbon neutrality propels the unremitting innovation of energy technologies [1], [2], [3], [4], [5], [6].

Environmentally friendly manufacture of battery electrodes

For realizing all-solid-state batteries (ASSBs), it is highly desirable to develop a robust solid electrolyte (SE) that has exceptional ionic conductivity and electrochemical stability at room temperature. While argyrodite-type Li6PS5Cl (LPSCl) SE has garnered attention for its relatively high ionic conductivity (∼3.19 × 10-3 S cm-1), it tends to emit hydrogen sulfide (H2S) in the.

Why We Invested in AM Batteries and Their Dry Electrode Technology

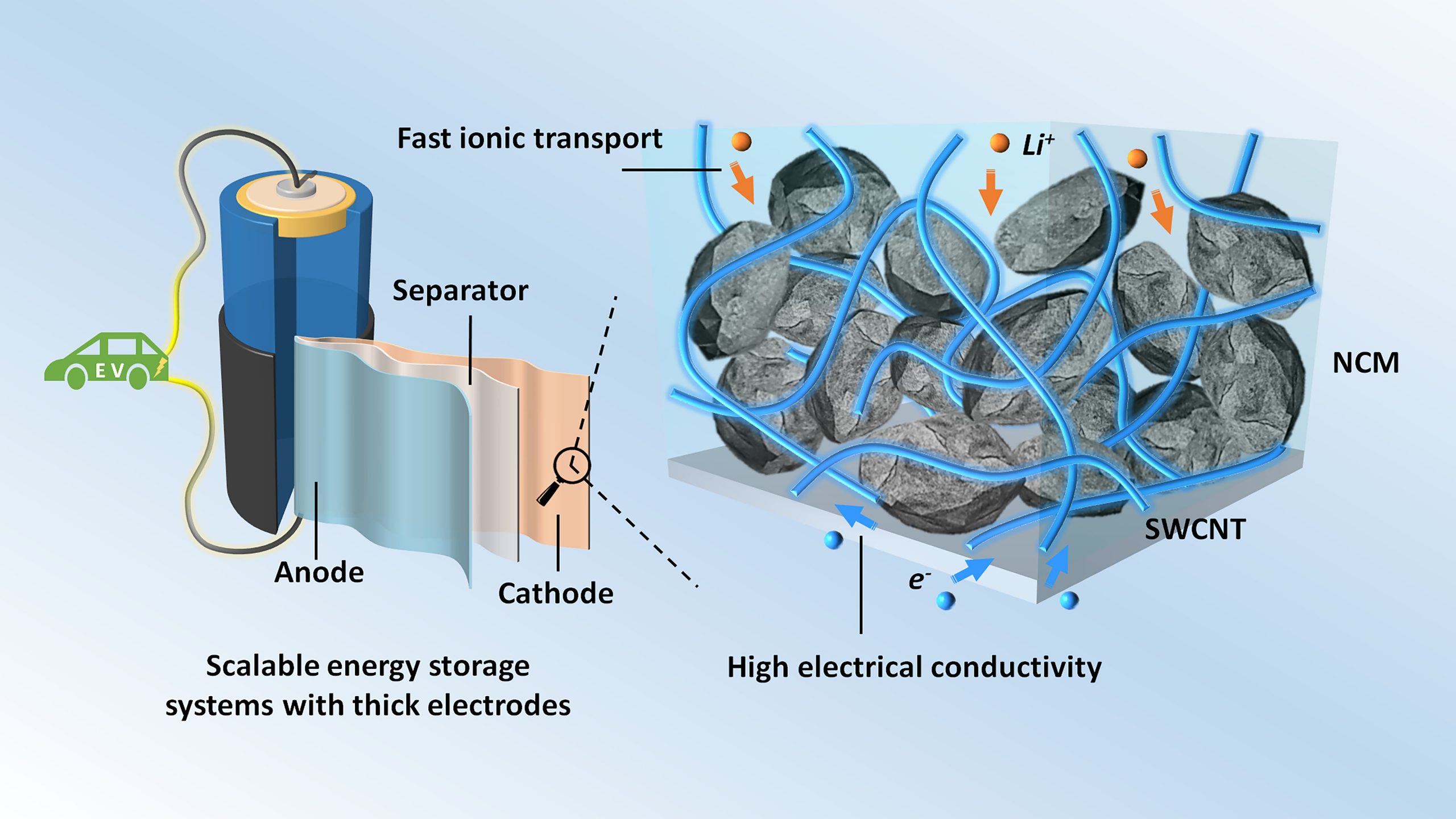

Commercially available Li-ion batteries range from as low as ~50 Wh kg −1, 80 Wh L −1 for high-power cells with a lithium titanium oxide (Li 4 Ti 5 O 12 or LTO) negative electrode, up to.

Maxwell Technologies (MXWL) Investor Presentation Slideshow (NASDAQ

Why dry coating electrodes is the future of the electric vehicle battery industry By Web Team December 3, 2021 6 Mins Read With global demand for batteries expected to increase from 185 GWh in 2020 to over 2000 GWh by 2030, finding more efficient production methods is a growing focus for the industry.

Batteries Free FullText Strategies and Challenge of Thick

March 10 (Reuters) - Tesla Inc (TSLA.O) is pioneering a new battery manufacturing process called dry electrode coating that it is applying to its new 4680 battery cells.

The Secret of Tesla Battery Day CleanTechnica

The need for energy-storage devices that facilitate the transition from fossil-fuel-based power to electric power has motivated significant research into the development of electrode materials for rechargeable metal-ion batteries based on Li +, Na +, K +, Mg 2+, Zn 2+, and Al 3+.The lithium-ion rechargeable battery (LIB) has been by far the most successful, enabling the wireless revolution of.

Buy Dry Electrode Preparation Solution,Dry Electrode Preparation

Fraunhofer IWS scientists have developed DRYtraec ®, a novel process that enables cost-efficient and environmentally friendly production of battery electrodes. It completely eliminates the use of toxic solvents as well as the energy- and cost-intensive drying of the electrode layers.

Tesla Giga Berlin's 4680 battery cells with DryElectrode coating

The dry process is considered a new electrode fabrication method for post-LIB electrodes since it offers unparalleled advantages in terms of operating cost and energy efficiency when compared.

Improving HighEnergy LithiumIon Batteries with Carbon Filler AIP

We will share electrochemical performance of dry battery electrode produced at the lab-level and pilot-level in single layer pouch cell as well as multilayer stacked pouch cell platform with capacity raging from about 200mAh to about 15Ah. References:

The Ultracapacitors, Electrodes, & Battery Manufacturing Tech Tesla

Dry battery electrode (DBE) is an emerging concept and technology in the battery industry that innovates electrode fabrication as a "powder to film" route. The DBE technique can significantly simplify the manufacturing process, reconstruct the electrode microstructures, and increase the material compatibilities.

Dry electrode technology, the rising star in solidstate battery

AM Batteries has found that this dry process results in 1) a 40% reduction in capital required for electrode equipment investment; 2) a 50% reduction in electricity usage of the plant; and 3.